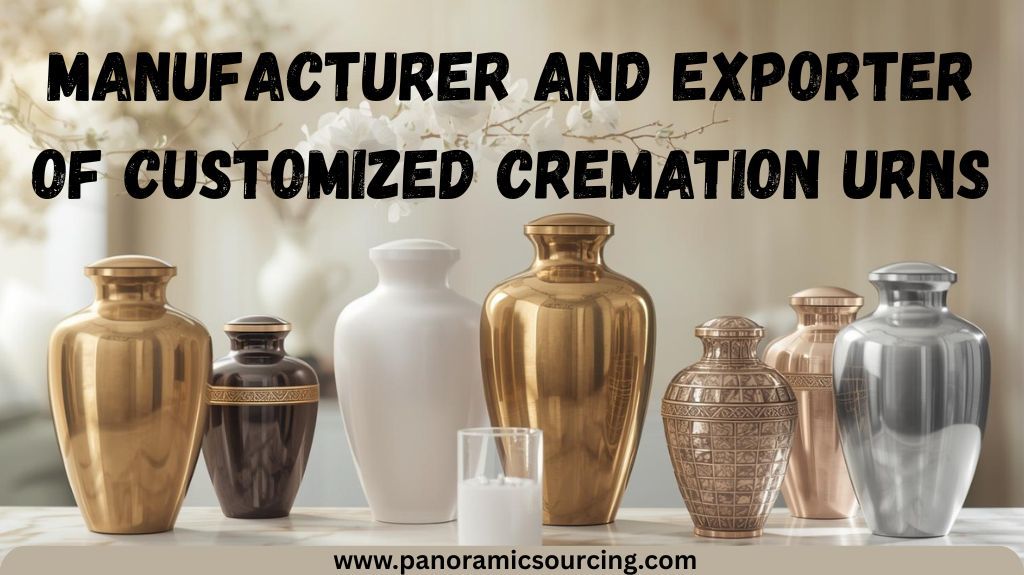

Manufacturer and Exporter of Customized Cremation Urns

Cremation Urns Manufacturing for Global Buyers

International buyers searching for reliable suppliers are not looking for generic information. They are evaluating production capability, export readiness and long-term consistency. As a professional manufacturer and exporter of Customized Cremation Urns, the focus is on delivering products that meet international standards while maintaining emotional sensitivity and design integrity.

From Moradabad’s metalworking ecosystem to structured global exports, the manufacturing process behind export-grade memorial vessels is both technical and highly specialized. Buyers in the United States and other international markets assess suppliers based on repeat production reliability, finish consistency and the ability to scale programs without compromising quality. This guide explains how export manufacturing works, the product categories demanded by global buyers and how sourcing oversight ensures consistency at every stage.

Moradabad as a Manufacturing Hub for Cremation Urns

Moradabad is globally recognized for its metal manufacturing heritage. Often referred to as the Brass City, Moradabad has built a strong export ecosystem around precision metal products, including Cremation Urns supplied to funeral homes and memorial distributors worldwide.

Manufacturers in Moradabad specialize in brass, aluminum and alloy-based production, supported by skilled artisans and modern machinery. What makes the region particularly suitable for global buyers is its ability to handle repeat bulk orders, maintain consistent finishes across batches and adapt designs for different cultural and market preferences in the US and Europe.

Another advantage Moradabad offers global buyers is ecosystem density. Tooling units, polishing houses, coating facilities and packaging vendors operate within close proximity, allowing manufacturers to control timelines more effectively. This integrated setup shortens production cycles and enables faster response to urgent export schedules, which is especially valuable for overseas buyers working with fixed retail or distribution timelines.

From a sourcing perspective, this concentration also allows quality checks to be conducted at multiple stages without logistical complexity. Buyers benefit from reduced transit handling between processes, resulting in fewer surface defects and improved finish durability upon arrival.

Manufacturing Processes Used in Urns Production

Casting, Spinning and Shaping

The production of metal memorial vessels begins with sand casting, die casting or metal spinning. Casting is used for decorative or complex shapes where depth and relief are required, while spinning is preferred for seamless, symmetrical forms. These processes ensure structural strength, balance and dimensional accuracy required for export programs involving Cremation Urns.

Precision Machining and Lid Engineering

Lid quality is a defining factor in premium memorial manufacturing. CNC machining is used to create precise threading, ensuring secure and airtight closure. This level of mechanical accuracy is closely evaluated by US buyers sourcing Cremation Urns for long-term storage and display.

Types of Cremation Urns Manufactured for Export Markets

Human Cremation Urns for Adult Memorials

Human Urns form the foundation of most export programs. These Cremation Urns are designed to hold full adult remains and must comply with international capacity expectations, typically around 200 cubic inches.

Export buyers expect:

Consistent internal capacity

Smooth, secure lid threading

Durable surface coatings

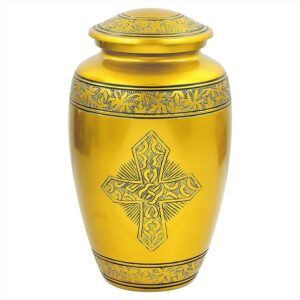

Timeless design aesthetics

Manufacturers offer adult memorial vessels in classic, contemporary and minimalist styles, with customization options for engraving, finish selection and private labeling aligned with US funeral industry requirements.

To help international buyers evaluate designs, finishes and size variations, we provide access to our complete Cremation Urns catalog, which includes adult vessels, pet memorial items for dogs, cats and rabbits, as well as keepsakes and heart keepsakes available for export.

Keepsake Cremation Urns for Shared Remembrance

Keepsakes are smaller vessels designed to hold a symbolic portion of ashes. These Cremation Urns are commonly ordered alongside full-size products as coordinated collections for funeral homes and memorial brands.

Precision is critical due to the smaller size. Even minor surface or threading defects become noticeable, making quality control essential for overseas buyers positioning keepsakes as premium remembrance items.

Heart-Shaped Keepsake Cremation Urns

Heart keepsakes are a specialized category that combines symbolic value with fine manufacturing detail. These Cremation Urns are produced using precision casting to achieve symmetrical shapes and secure micro-threaded closures.

They are particularly popular in the US market as mantlepiece memorials or remembrance gifts, requiring flawless finishing, protective coatings and export-safe packaging.

Pet Cremation Urns for Dogs, Cats and Rabbits

Pet memorialization is a rapidly growing segment in the United States. Manufacturers supplying pet memorial products must match the same quality standards used for human remembrance items.

- Dog vessels are typically larger and often include paw prints or engraved motifs.

- Cat memorial vessels favor refined, compact designs with smooth finishes.

- Rabbit and small-pet items require miniature formats with highly secure closures.

Export buyers increasingly prefer suppliers who can offer a complete pet range rather than fragmented sourcing.

Customization Capabilities in Urns Manufacturing

True differentiation lies in customization. As an export-focused supplier, customization must be scalable, repeatable and precise across product categories.

Common customization options include:

Laser-engraved names, dates and quotes

Symbolic or themed artwork

Color matching for private labels

Size variations across adult, pet and keepsake formats

From a commercial standpoint, customization must be supported by clear approval workflows. Export buyers typically require pre-production samples, engraving proofs and finish swatches before confirming bulk orders. Manufacturers who can manage these stages efficiently reduce delays and build long-term buyer confidence.

Repeatability is equally important. Once a customized design is approved, the supplier must be capable of reproducing it consistently across future orders without deviation. This capability is essential for brands maintaining standardized catalogs year after year.

Materials Used in Urns Manufacturing

Metal Memorial Vessels

Brass, aluminum and copper are the most widely used materials. Brass offers weight and a premium feel, while aluminum provides corrosion resistance and lighter handling. All metal vessels are finished with protective lacquer to prevent tarnishing during storage and international transit.

Wooden Memorial Vessels

Hardwoods such as Sheesham, Mango wood and Walnut are kiln-dried to prevent cracking. Wooden vessels offer a warmer aesthetic and are popular for indoor memorial settings.

Marble and Natural Stone

Stone memorial vessels are carved from solid blocks, ensuring permanence and uniqueness. Natural variation in veining makes each piece one of a kind.

Export Readiness and What Global Buyers Evaluate

For US and international buyers, appearance alone is not enough. Export-ready production requires:

Consistent batch manufacturing

International packaging standards

Experience with US and EU documentation

Clear production timelines and communication

Manufacturers lacking export discipline often create risks for overseas buyers. Exporting memorial products requires alignment with internationally recognized trade and compliance standards. Organizations such as the EPCH (Export Promotion Council for Handicrafts) support exporters with documentation frameworks and international trade guidelines.

Packaging plays a critical role in export success. Products must be protected not only against impact but also against surface abrasion and moisture exposure. Export-grade packing typically includes individual protective wraps, inner cushioning and reinforced outer cartons designed for pallet stacking. Buyers often assess packaging quality as an extension of manufacturing discipline.

Clear labeling, batch identification and packing lists further support smooth customs clearance and warehouse handling upon arrival in destination markets.

The Role of Panoramic Sourcing in Export Operations

Panoramic Sourcing acts as the operational backbone connecting Indian manufacturers with global buyers. Rather than operating as a trader, Panoramic Sourcing manages sourcing, quality and export processes end-to-end.

How Panoramic Sourcing Manages the Entire Process

Manufacturer Vetting and Selection

Factories are shortlisted based on production capability, export experience and quality systems.

Quality Control and Inspection

In-process inspections, final quality checks and random sampling are conducted before shipment.

Packaging and Export Logistics

Each unit is individually protected, boxed, palletized and shipped with full export documentation.

Manufacturer and Exporter Alignment for Global Markets

Many factories manufacture memorial vessels but lack structured export capability. Successful global supply depends on aligning manufacturing strength with export management to ensure consistency and reliability.

Conclusion

Sourcing memorial products requires precision, empathy and accountability. From manufacturing clusters to structured export execution, every stage matters.

By combining skilled production with professional sourcing oversight, global buyers gain confidence in quality, timelines and consistency, ensuring long-term supply reliability.

FAQs

1. What is the capacity of Adult Human Urns?

Most adult vessels hold approximately 200 cubic inches.

2. Are pet memorial products customizable?

Yes, customization is available for dogs, cats, rabbits and other small pets.

3. What makes Moradabad suitable for export manufacturing?

Skilled artisans, export infrastructure and advanced finishing expertise.

4. How is quality ensured before export?

Through multi-stage inspections, lid testing, finish checks and packaging verification.

5. Why work with a sourcing partner?

To reduce risk, ensure compliance and protect brand reputation.