Private Label Sourcing India: A Global Buyer’s OEM & ODM Brand Framework

In global retail today, ownership of product identity matters more than ever. Brands that control design, specifications, and manufacturing gain pricing power, customer loyalty, and long-term defensibility. This shift is why Private label sourcing India has become a strategic pathway for businesses seeking to move beyond reselling and into true brand ownership.

For global buyers, the objective is no longer limited to sourcing products at competitive prices. The focus has expanded to building exclusive collections, managing intellectual property, and scaling production through reliable manufacturing systems. India’s diverse industrial base, flexible production capacity, and experience with international markets make it a critical destination for OEM and ODM brand development.

This article explains the private label model from a brand-first perspective. It breaks down how global companies implement OEM and ODM strategies, how factories are evaluated, how quality is enforced, and how supply chains are structured for long-term growth.

Understanding the Private Label Brand Model in a Global Context

At its core, private labeling allows a business to sell products under its own brand while outsourcing manufacturing. What differentiates advanced brand builders from basic resellers is control—control over design, materials, quality standards, and future iterations.

Private label sourcing India supports this control because the manufacturing ecosystem spans raw material processing, component manufacturing, assembly, and finishing within one country. This vertical depth allows buyers to influence product outcomes more precisely than in fragmented sourcing models.

For global brands, private labeling is not a shortcut. It is a structured process that requires technical planning, documentation, and governance across the supply chain.

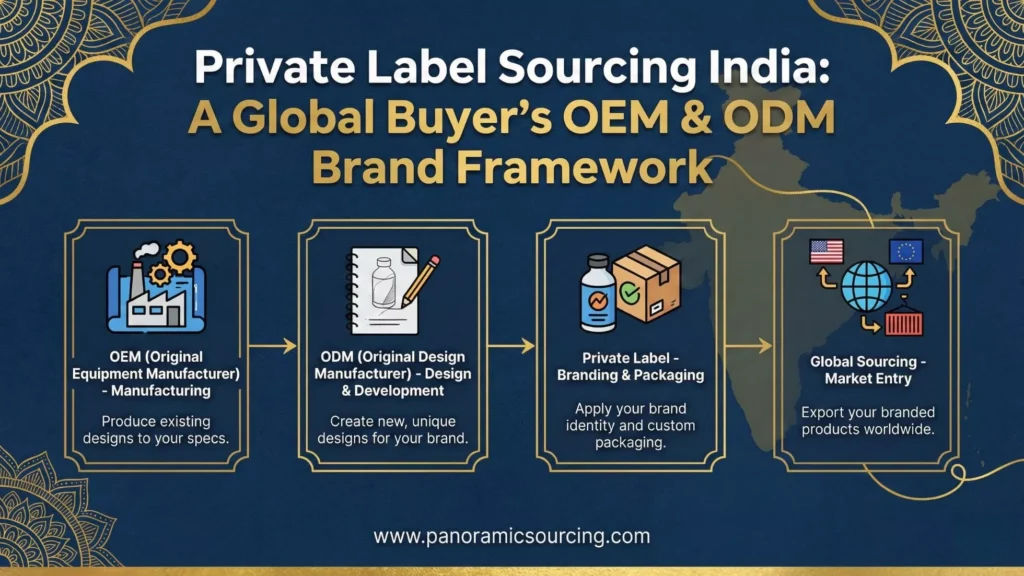

OEM vs ODM: Two Distinct Paths to Brand Ownership

Private label manufacturing generally follows one of two models. Understanding the difference is essential before approaching factories.

Original Equipment Manufacturing (OEM)

OEM is the most customized approach. The buyer owns the design and provides complete product specifications. Factories act purely as execution partners, producing items exactly as instructed.

Within Private label sourcing India, OEM is preferred when:

The brand has proprietary designs or patented concepts

Product differentiation is central to market positioning

Long-term exclusivity is required

OEM projects demand higher upfront investment due to tooling, development time, and testing. However, they provide the strongest brand protection and pricing leverage.

Original Design Manufacturing (ODM)

ODM is a faster route to market. Factories develop products internally and offer them as customizable bases. Buyers adapt branding, colors, materials, or packaging while retaining the core design.

Global brands often use ODM when:

Launching new categories quickly

Testing demand before committing to OEM

Entering seasonal or trend-driven markets

In Private label sourcing India, ODM works well in categories such as home décor, textiles, accessories, and lifestyle goods where factories maintain active design libraries.

Defining Brand Readiness Before Factory Engagement

Many sourcing failures occur before the first supplier conversation. Successful private label programs begin with internal clarity.

Before engaging in Private label sourcing India, buyers should define:

Target customer profile

Price positioning (mass, mid-market, premium)

Compliance requirements by destination country

Expected order volumes over 12–24 months

Factories assess buyers as carefully as buyers assess factories. Brands with clear documentation and realistic projections receive better pricing, priority capacity, and stronger collaboration.

Factory Selection Criteria for OEM and ODM Projects

Not all manufacturers are equipped for private label production. The evaluation process must go beyond capacity and pricing.

Key factory attributes include:

Experience with export markets

In-house development or engineering teams

Ability to manage customized packaging and labeling

Social and environmental compliance maturity

In Private label sourcing India, factory specialization varies by region and product category. Aligning brand requirements with factory strengths reduces development delays and quality risks.

Sampling as a Brand Control Mechanism

Sampling is not a formality; it is a governance tool.

A structured sampling sequence typically includes:

Concept or proto samples

Functional testing samples

Final approval samples (“Golden Sample”)

The Golden Sample becomes the legal and technical benchmark for production. Any deviation from it constitutes a non-conformance. In Private label sourcing India, disciplined buyers never proceed to bulk production without documented sample approval.

Quality Management in Private Label Manufacturing

When selling under a private label, responsibility for quality rests entirely with the brand. Factory QC systems alone are insufficient for global markets.

Effective quality programs include:

Pre-production material verification

In-line production inspections

Final random inspections based on AQL standards

For brands sourcing through Private label sourcing India, third-party inspections are commonly used to maintain independence and documentation integrity.

Compliance and Regulatory Alignment Across Markets

Private label brands must meet destination-country regulations, not just factory norms.

Global brands operating OEM and ODM programs typically require manufacturers to align with internationally recognized management and quality standards published by the International Organization for Standardization, which form the foundation for consistent production, compliance, and process control across borders.

Depending on product category, compliance may include:

Material safety and chemical restrictions

Labeling and origin disclosure

Sustainability or traceability requirements

Indian factories serving private label clients are generally familiar with global compliance frameworks, but buyers must ensure alignment early in development.

Role of Sourcing Partners in Managing OEM/ODM Complexity

Managing OEM or ODM projects remotely introduces coordination challenges. Time zones, language differences, and factory capacity constraints require constant oversight.

This is where professional sourcing partners add value.

Strategic Support via Panoramic Sourcing

Panoramic Sourcing operates as a buying office for global brands managing OEM and ODM programs in India. Their role includes factory identification, technical coordination, sample management, compliance verification, and production monitoring.

For buyers implementing Private label sourcing India at scale, such partners reduce operational friction and provide real-time visibility into factory execution.

Cost Structure and Financial Planning

Private label sourcing requires a broader financial view than unit pricing alone.

Buyers must calculate:

Product cost (FOB)

Tooling and development costs

Quality inspection expenses

Freight, duties, and insurance

In Private label sourcing India, MOQs are often more flexible than other global hubs, allowing brands to scale gradually without excessive inventory exposure.

Logistics and Shipment Optimization

Shipping strategy directly impacts margins and delivery reliability.

Private label buyers often consolidate shipments from multiple factories into full-container loads. This reduces per-unit freight costs and simplifies customs clearance.

India’s port infrastructure and export experience support both FCL and LCL strategies, making Private label sourcing India adaptable to different business sizes.

Managing Intellectual Property and Design Security

Design protection is a legitimate concern in private labeling. Buyers should implement safeguards such as:

NDAs before design sharing

Clear ownership clauses in manufacturing agreements

Limited design access within factories

Indian contract manufacturing environments are increasingly structured around export compliance, but legal clarity remains essential.

Timeline Expectations for Private Label Launches

From concept to delivery, private label timelines typically include:

Development and sampling: 4–8 weeks

Tooling and pre-production: 2–4 weeks

Bulk production: 30–60 days

Sea freight: 25–40 days

Brands using Private label sourcing India should plan launches with buffer time for revisions and inspections.

Long-Term Scaling Through the Indian Supply Chain

Private labeling is not a one-off transaction. Successful brands use early orders to refine specifications, reduce costs, and improve packaging efficiency.

India’s manufacturing ecosystem supports:

Product line extensions

Seasonal updates

Material substitutions for cost or sustainability goals

This scalability is a key reason global companies commit to Private label sourcing India as a long-term strategy.

Conclusion

Private labeling transforms a business from a seller into a brand owner. By leveraging OEM and ODM manufacturing models, global buyers gain control over product identity, quality, and market positioning.

Private label sourcing India offers a rare combination of manufacturing depth, customization flexibility, and export readiness. When approached with structured planning, disciplined quality control, and the right partners, it becomes a powerful engine for global brand growth.

FAQs

What is the main difference between OEM and ODM?

OEM involves building a product from the buyer’s design, while ODM adapts an existing factory design.

Is private labeling suitable for small brands?

Yes. Flexible MOQs and phased scaling make it accessible.

How do buyers protect their designs?

Through NDAs, contracts, and controlled design sharing.

Can packaging be customized?

Yes. Packaging customization is standard in private label programs.

How long does a private label launch take?

Typically 4–6 months from development to delivery.