How to Find Reliable Suppliers in India — Directories, Trade Shows & Factory Audits Explained

Global buyers across the UK, USA, Australia and Canada increasingly source from India due to its skilled manufacturing base, diversified supplier ecosystem and export-ready infrastructure. However, understanding how to find suppliers in India goes far beyond online searches or price comparisons. The real challenge lies in identifying reliable suppliers who can consistently meet quality standards, delivery timelines, and regulatory requirements across repeated orders.

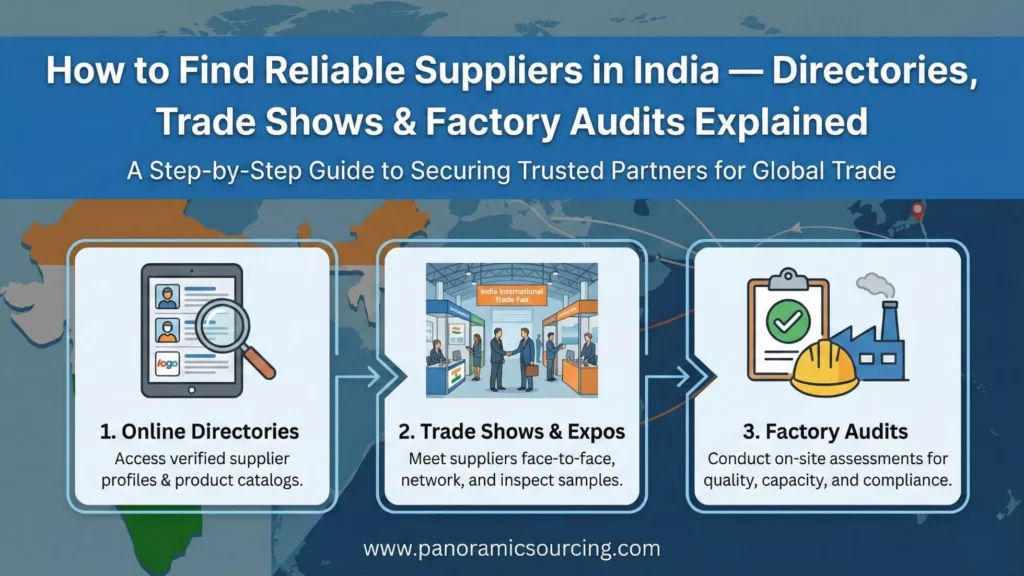

This guide explains how to find suppliers in India using three proven pillars—supplier directories, trade shows and factory audits. Rather than treating sourcing as a one-time activity, experienced buyers follow a layered verification approach that significantly reduces commercial risk and improves long-term sourcing outcomes.

What “Reliable Suppliers” Mean in the Indian Sourcing Context

Before applying any discovery method, buyers must clearly define reliability. In India, reliability is not determined by company size or quoted price alone, which is a common misconception among first-time buyers learning how to find suppliers in India.

Reliable suppliers demonstrate stable production capacity, documented quality control systems, repeat export experience, and disciplined communication. They are able to reproduce approved quality across multiple production cycles and comply with destination-market regulations without constant buyer intervention.

For buyers in regulated markets such as the UK, USA, Australia and Canada, supplier reliability directly impacts customs clearance, compliance audits, brand reputation and inventory planning.

Buyer Reality Check: What Commonly Goes Wrong

Many buyers researching how to find suppliers in India encounter predictable issues during early sourcing attempts:

Online profiles that exaggerate manufacturing capability

Samples that do not represent bulk production quality

Overstated capacity and underestimated lead times

Compliance gaps discovered only at shipment stage

These issues explain why professional buyers never rely on a single discovery method when deciding how to find suppliers in India for long-term sourcing.

Supplier Directories: Using Them Correctly for Initial Supplier Discovery

Supplier directories are usually the first place buyers begin when researching how to find suppliers in India, mainly because they provide fast visibility into a wide supplier base. However, directories are only effective when buyers understand their limitations and apply structured filtering.

What Supplier Directories Are and Are Not

Supplier directories function strictly as lead-generation tools. They list companies willing to supply products but do not confirm whether those companies own factories, subcontract production or maintain quality systems. Treating the directory itself as verification is one of the most common sourcing mistakes.

Widely Used Supplier Directories by Global Buyers

In real sourcing practice, buyers rely on a limited set of platforms:

IndiaMART for broad manufacturer discovery

TradeIndia for export-oriented supplier listings

Export-body listings such as the Federation of Indian Export Organizations (FIEO) for legitimacy checks

https://www.fieo.orgIndustry association member directories in textiles, handicrafts, leather and engineering

These sources help buyers understand availability, not supplier reliability.

How Experienced Buyers Actually Use Directories

When applying how to find suppliers in India through directories, experienced buyers:

Shortlist 10–15 suppliers to account for attrition

Eliminate suppliers without export history or clear manufacturing disclosure

Prioritize listings showing factory images, certifications and narrow product focus

Treat quoted prices as indicative, pending validation

Buyers rarely finalize suppliers directly from directories without further checks.

Practical Risks of Over-Reliance on Directories

Directories do not reveal subcontracting practices, internal quality controls or real production capacity. Buyers who skip further validation often face inconsistent quality, delayed shipments or commercial disputes that could have been avoided with deeper verification.

Trade Shows in India: Evaluating Suppliers Beyond Online Profiles

Trade shows provide the second verification layer and remain one of the most effective ways to apply how to find suppliers in India in real operating environments.

Why Trade Shows Matter for Global Buyers

Trade shows attract export-facing suppliers prepared to engage with international buyers. Buyers can evaluate communication ability, product consistency across samples and professionalism in real time—something directories cannot provide.

Major Indian Trade Shows Used by Global Buyers (2024–2025)

Buyers commonly attend:

IHGF Delhi Fair for handicrafts, home décor and lifestyle products

India International Trade Fair for multi-sector sourcing

Textile exhibitions in Tiruppur, Noida and Surat

Engineering and metal fabrication expos in Pune and Coimbatore

Suppliers at these events are generally familiar with export documentation and buyer compliance expectations.

How Buyers Prepare Before Attending Trade Shows

Effective buyers attend trade shows with:

Defined product specifications and tolerance levels

Target pricing and volume ranges

Compliance and certification requirements

Without preparation, trade shows become browsing exercises rather than strategic steps in how to find suppliers in India.

How Buyers Evaluate Suppliers During Trade Shows

Buyers assess:

Consistency across multiple samples

Transparency regarding production capacity and lead times

Understanding of export markets served

Willingness to share factory and audit access

Suppliers who avoid operational questions are rarely shortlisted.

Post-Trade Show Shortlisting Strategy

Trade shows should lead to structured follow-up, not immediate orders. Reliable suppliers respond promptly, share documentation and cooperate with audits. Buyers typically shortlist 3–5 suppliers for factory verification after trade shows.

Factory Audits Explained: Confirming Reality Before Commitment

Factory audits represent the final and most decisive step in determining how to find suppliers in India who are genuinely capable of long-term supply.

What Factory Audits Cover in Practice

A comprehensive factory audit evaluates:

Manufacturing setup and machinery condition

Workforce size versus claimed capacity

In-process quality checkpoints

Storage, packaging, and traceability systems

Documentation and compliance practices

Audits confirm whether suppliers can consistently meet approved specifications at scale.

Common Issues Revealed Through Factory Audits

Audits frequently uncover:

Undisclosed subcontracting

Inflated capacity claims

Informal or undocumented quality controls

Labor safety or regulatory gaps

These risks are rarely visible through directories or trade shows alone.

First-Party vs Third-Party Factory Audits

First-party audits are conducted by buyers or their representatives. Third-party audits provide independent validation and are commonly used by global buyers unable to be physically present in India.

Why Audits Matter Even for Small Orders

Many buyers assume audits are only necessary for large volumes. In practice, audits prevent long-term dependency on unreliable suppliers, even for pilot orders, making them essential to any serious strategy on how to find suppliers in India.

How Buyers Combine Directories, Trade Shows, and Factory Audits

Reliable sourcing outcomes come from combining all three methods rather than relying on one.

| Method | Primary Role | Key Limitation |

|---|---|---|

| Supplier Directories | Initial discovery | No verification |

| Trade Shows | Supplier evaluation | Limited depth |

| Factory Audits | Final confirmation | Requires shortlisting |

Directories identify options, trade shows narrow choices and audits confirm reliability.

2025 Trends Influencing How to Find Suppliers in India

Understanding how to find suppliers in India in 2025 requires awareness of evolving sourcing dynamics:

Accelerating China+1 sourcing strategies

Growing demand for lower MOQs from first-time India buyers

Higher compliance expectations from UK and EU markets

Preference for audited and traceable suppliers

Increased reliance on professional sourcing partners

When Global Buyers Use Sourcing Partners

As sourcing complexity increases, many buyers delegate execution to professionals. Sourcing partners manage directory shortlisting, represent buyers at trade shows, conduct factory audits and coordinate supplier onboarding—reducing trial-and-error sourcing.

Why Panoramic Sourcing Is a Practical Option for Global Buyers

Panoramic Sourcing is commonly used by global buyers seeking a structured approach to how to find suppliers in India without building local teams. Buyers typically engage Panoramic Sourcing after initial directory or trade show shortlisting, relying on the firm for audits, supplier verification, quality oversight and export coordination.

This execution-driven model supports buyers in the UK, USA, Australia and Canada by reducing sourcing risk and improving long-term supplier reliability.

Conclusion: Reliable Supplier Discovery Requires Structure

Learning how to find suppliers in India is not about choosing one method. Reliable sourcing comes from layered verification—directories for discovery, trade shows for evaluation and factory audits for confirmation.

Buyers who treat supplier discovery as a structured verification process rather than a one-time search consistently achieve better quality control, compliance and supply chain stability.

Frequently Asked Questions

1. Are supplier directories enough for finding reliable suppliers in India?

No. Directories support discovery but require verification.

2. Do trade shows guarantee supplier reliability?

No. Trade shows identify export-ready suppliers but do not replace audits.

3. Are factory audits necessary for small orders?

Yes. Audits prevent long-term sourcing risk.

4. How long does supplier verification usually take?

Typically 3–6 weeks including audits.

5. Why do global buyers use sourcing partners?

To manage discovery, verification, audits and coordination efficiently.